The Problem

Cold Start Wear Is The #1 Source of Engine Damage

Every engine ever built suffers from the same fatal flaw:

It starts without oil pressure

Of All Engine Wear

Occurs during cold starts when there is zero hydrodynamic oil film protection

Critical Window

Metal-to-metal contact happens in the first 1-3 seconds before oil pressure builds

Oil Pressure At Start

The crankshaft rests directly on bearings with zero hydrodynamic lift

What Happens During A Cold Start

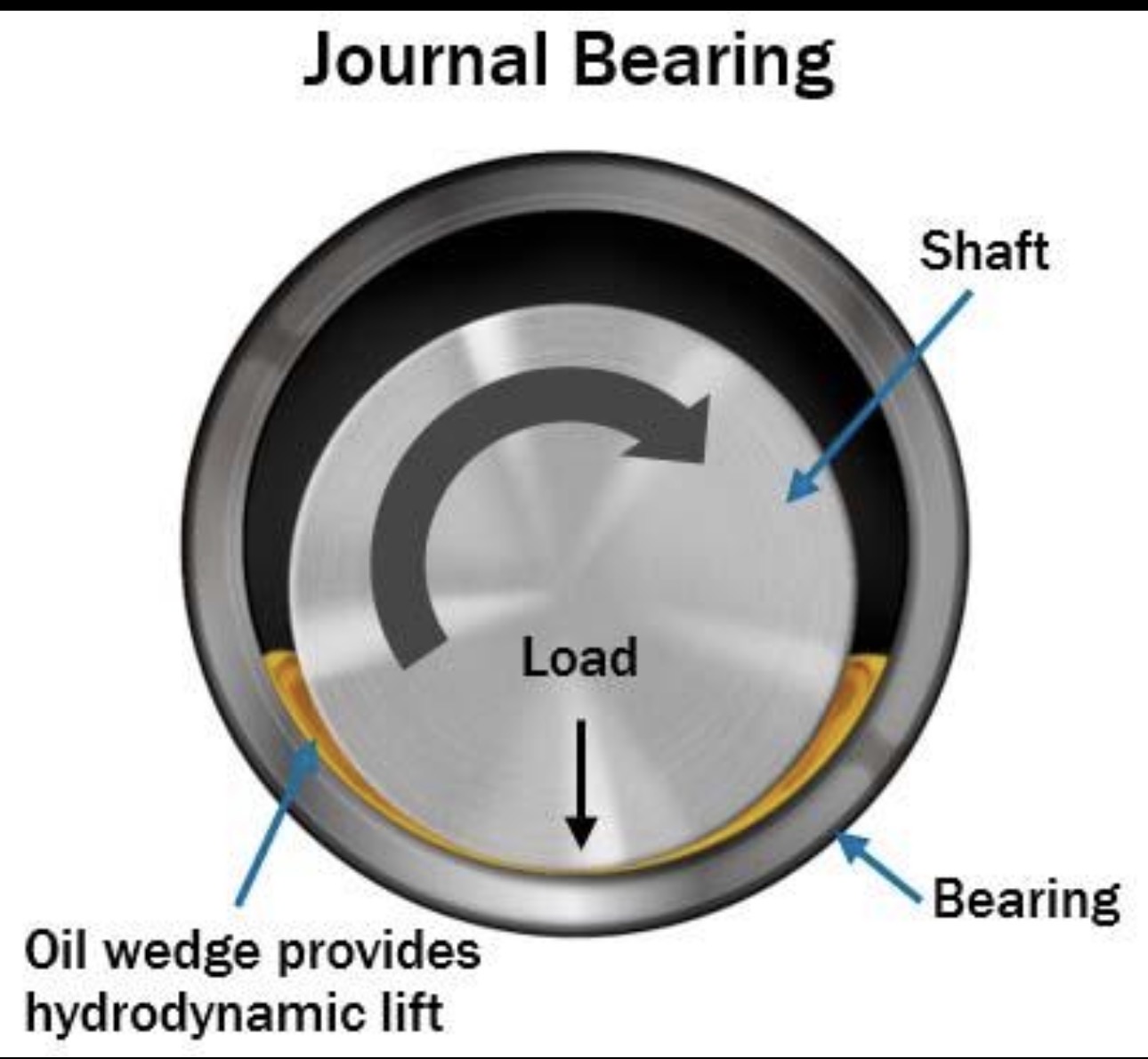

Journal bearing surface showing damage from repeated cold-start wear

1. Engine Is At Rest

When an engine sits idle, oil drains back to the pan. The crankshaft, camshaft, and connecting rods settle onto their bearing surfaces with no separation.

- No hydrodynamic oil film exists

- Journal surfaces in direct contact with bearing overlay

- Oil pressure gauge reads zero

2. Starter Motor Engages

The starter begins rotating the crankshaft. But there's still no oil pressure—the mechanical pump can't build pressure until the engine is already spinning.

- Crankshaft journals grind against bearing surfaces

- Cam lobes scrape lifters and followers

- Connecting rod bearings experience metal-to-metal contact

3. Oil Pressure Builds Slowly

After 1-3 seconds of unprotected rotation, oil finally reaches critical bearing surfaces. But the damage is already happening.

- Bearing overlay material sheds microscopic particles

- Clearances increase over thousands of starts

- Metal contamination enters the oil

4. Cumulative Damage

This process repeats every single time the engine starts. Over tens of thousands of cold starts:

- •Bearing clearances increase beyond specification

- •Oil pressure drops at idle

- •Timing chains stretch

- •Cam lobes flatten

- •Turbos develop shaft play

- •Engine life is dramatically shortened

What Cold Starts Destroy

Main Bearings

The crankshaft journals grind the soft bearing overlay layer, creating metal particles and increasing clearance.

Rod Bearings

Connecting rod journals experience the highest loads during combustion—without oil film, micro-scuffing is inevitable.

Cam Lobes & Lifters

Overhead cam engines are especially vulnerable. High spring pressure + no oil = accelerated lobe wear.

Turbochargers

Turbo bearings rely on hydrodynamic lift. Dry startup is the #1 cause of turbo failure—bearings scuff and develop shaft play.

Timing Chains

Dry startup delays proper lubrication to chain guides and tensioners, accelerating stretch and wear.

Piston Rings

Without cylinder wall lubrication, rings scrape dry metal, leading to blow-by and oil consumption.

Cold Weather Makes It Worse

At low temperatures, oil viscosity increases dramatically. Thick, cold oil takes even longer to reach critical bearing surfaces.

0°F (-18°C)

Oil is 10x more viscous. It can take 5-10 seconds for proper oil pressure to stabilize.

-20°F (-29°C)

Extreme cold makes oil flow like honey. Wear rate can be 20x higher than a warm start.

The Industry Has Accepted This Failure

For over a century, automakers have known about cold-start wear. But no consumer-friendly solution has ever existed—until now.

Every Vehicle Ever Built Suffers From This

- •Fleet vehicles with frequent starts experience shortened engine life

- •Municipal trucks, delivery vehicles, taxis—all suffer accelerated wear

- •Performance engines with tight clearances fail even faster

- •Cold-climate operation dramatically reduces engine longevity