How It Works

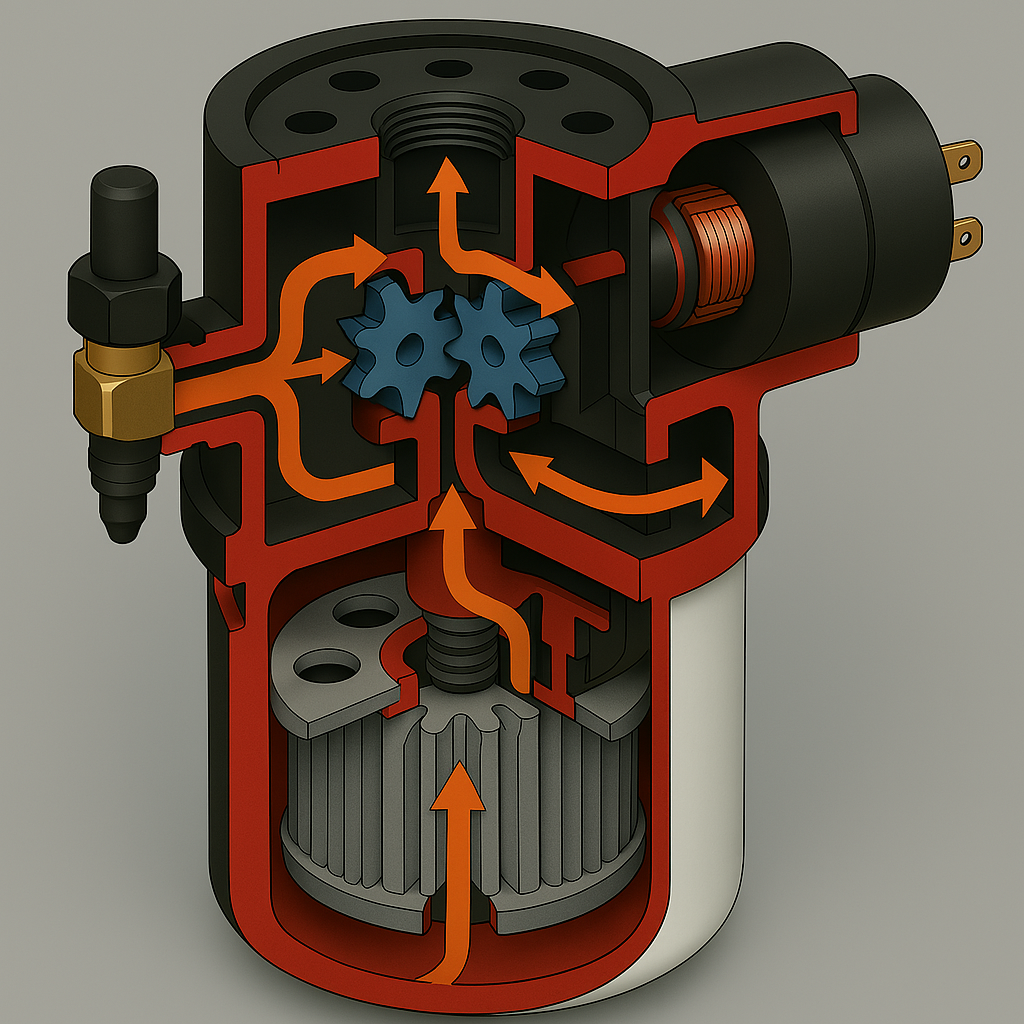

The No Dry Starts® system solves cold-start wear by building full oil pressure

before the engine ever cranks

The Complete Start Sequence

Key Turn Detection

When the driver turns the ignition key or presses the START button, our intelligent controller immediately detects the signal.

- •Instant electronic detection

- •No delay in driver experience

- •Compatible with push-button and key ignition

Electric Pump Activation

Our integrated electric oil pump fires instantly, drawing oil from the pan and forcing it through the engine galleries.

- •High-flow electric pump (not mechanical)

- •Fully self-contained sandwich-mount design

- •No external hoses or reservoirs

Oil Galleries Fill

The pump floods all critical bearing surfaces: mains, rods, cam journals, turbo bearings, and valve train components.

- •Crankshaft journals lifted on oil film

- •Camshaft bearings fully lubricated

- •Turbocharger bearings protected from dry spin

Pressure Verification

Our integrated pressure sensor monitors oil pressure in real-time, ensuring safe levels are achieved before allowing ignition.

- •Real-time pressure monitoring

- •Lockout controller prevents premature start

- •Typically 1-2 seconds to achieve target pressure

Protected Start

Only after full pressure is confirmed does the system release the starter motor. The engine cranks with zero metal-to-metal contact.

- Zero dry-start wear

- Hydrodynamic film established before rotation

- Engine starts as if already warmed up

System Components

Self-contained sandwich-mount design - installs between oil filter and engine block

Electric Pump Module

- •High-flow electric oil pump

- •Sandwich-mount design (installs like oil filter adapter)

- •No external plumbing required

- •Self-contained, sealed unit

Pressure Sensor

- •Integrated pressure monitoring

- •Real-time feedback to controller

- •Prevents premature start

- •Fail-safe design

Ignition Controller

- •Intelligent lockout system

- •Integrates with OEM ignition

- •Releases starter only after pressure OK

- •Universal compatibility

Simple Installation

Mounting

Installs between engine block and oil filter using a sandwich adapter—just like an oil cooler or remote filter kit. No custom fabrication required.

Wiring

Simple 3-wire connection: Power, Ground, and Ignition Signal. Integrates with existing starter circuit.

Compatibility

Universal design fits gasoline, diesel, turbocharged, naturally aspirated, and performance engines. Cars, trucks, fleets, and marine applications.